ELECTROMAGNETIC PULSE (EMP) AND TEMPEST PROTECTION FOR FACILITIES

Table of Contents: http://jya.com/emp.htm

------------------------------------------------------------------------------

CHAPTER 3

EMP HARDENING CONCEPTS FOR FACILITIES

3-1. Outline. This chapter is organized as follows:

3-1. Outline

3-2. Discussion of general concepts

a. System functions

b. Survival confidence

(1) Levels of confidence

(2) Inherent uncertainties

c. Critical equipment sensitivities

(1) Design margin

(2) Coupled energy

d. Potential HEMP coupling paths

e. Design verifiability

(1) Hardness validation

(2) Retrofit designs

(3) Designing to facilitate testing

(4) Approaches to validation

f. Physical environment

g. Other factors

3-3. Description of HEMP hardening concepts

a. Shielding

(1) Global shielding

(2) Tailored shielding

(3) Zonal or topological shielding

(4) System configuration

(5) Cable shielding

(6) Grounding

b. Hardening allocation concept

c. Shield penetration protection concepts

(1) Large access doors

(2) Personnel entrances

(3) Electrical penetrations

(4) Transient suppression devices and filters

(5) Electromagnetic isolation

(6) Dielectric isolation

(7) Isolation switching

3-4. Cited references

3-5. Uncited references

------------------------------------------------------------------------------

3-2. Discussion of general concepts. The HEMP environment is defined by DOD-

STD-2169. This definition includes the classification and specific

information on field strengths, pulse characteristics, spectral content, angle

of arrival, range of relative burst locations, and weapon yield.

a. System functions. Associated with the electronic and electrical

systems and subsystems to be protected are support functions such as

utilities, personnel housing, office space, document storage, food facilities,

and others. Many aspects of a facility are not sensitive to HEMP energy or

are robust enough that HEMP protection is not required. Some sensitive system

elements may not be critical to the facility mission. The definition of

mission-essential functions that must remain in operation will have major

impact on the choice of hardening concepts.

b. Survival confidence. The issue of defining "survivability

requirements" must be specifically addressed and resolved in the concept

definition phase of each particular HEMP hardening effort. The system user

should define the required survival confidence level, at least qualitatively,

since this factor will determine how conservative the design will be. If

required confidence levels are high, greater safety margins in protection

levels will be required, producing a need for a high-quality overall shield

and adequate validation testing.

(1) Levels of confidence. Survivability confidence may require that a

facility--

(a) Experience no HEMP-induced stress greater than the stresses

occurring in the normal operating environment.

(b) Experience neither permanent nor operational upset as a result

of the HEMP.

(2) Inherent uncertainties. Another survivability issue concerns the

inherent and analytical uncertainties in quantifying the stress level causing

malfunction or the stress level experienced by the equipment.

c. Critical equipment sensitivities. The main factors in determining

required protection levels are--

(1) Design margin. The design margin required, which is related to the

difference between critical equipment sensitivities and coupled transients.

(2) Coupled energy. The energy level coupled from connected subsystems

or components.

d. Potential HEMP coupling paths. Most electronic/ electrical systems to

be HEMP-hardened and their housing facilities will have to interface with

external elements such as antennas, utilities, communications lines, and other

facilities. The complexity of interfacing and possible coupling paths for

HEMP energy will greatly affect the choice of topological approaches to HEMP

hardening.

e. Design verifiability.

(1) Hardness validation. A key issue in HEMP hardening philosophy and

associated design concepts is that of hardness validation and required confi-

dence levels for final acceptance. (Required confidence levels are usually

specified only qualitatively.) Generally, the more critical the facility is

to national military security, the more politically and publicly visible it

will be; for these facilities, higher confidence levels will be required. In

all cases, design concepts may not be chosen if they cannot be validated with

acceptable confidence levels. For example, a design concept for a large

underground facility that depends on a degree of protection from the overbur-

den and has numerous conducting penetrations through the overburden may have

hardness uncertainties. Examples include questions about the homogeneity of

the overburden and difficulties in protecting penetrations when no highly

conductive shield is present. If the facility is too large to be practically

subjected to a threat level test by an EMP simulator and no other proven vali-

dation tests exist, the uncertainties will prevail and hardness confidence

will be low.

(2) Retrofit designs. In retrofit designs, another consideration-in

concept selection may be the ability to validate hardness without disrupting

the operation of critical systems. Concepts should be chosen to allow

nondisruptive validation and acceptance testing.

(3) Designing to facilitate testing. Good design validation requires a

choice of design concepts that facilitate testing. HEMP hardening management

must include adequate funding and scheduling for this effort. The difficulty

and cost of validation will increase with--

(a) System complexity.

(b) Topology layer and zone numbers.

(c) The number of required penetrations.

(d) The protective design philosophy.

(4) Approaches to validation. In considering the validation problem

for concept selection, it is helpful to review the many approaches to valida-

tion, including laboratory testing, full-scale HEMP threat level field

testing, partial scale threat-level field testing, current injection testing,

scale model testing, physical modeling testing, computer modeling evaluations,

analyses, and radio frequency CW shielding tests.

f. Physical environment. Various aspects of the facility physical

environment can greatly affect concept selection, mainly in the degree to

which corrosion can accelerate aging and degradation of protection.

g. Other factors. Other factors to be considered in concept selection

are--

(1) Complexity of required interactions with facilities.

(2) Design and construction costs.

(3) Constructibility.

(4) Maintenance costs.

(5) Reliability requirements.

(6) Flexibility for expansion or system changes.

(7) New construction versus retrofit.

(8) Supportability.

3-3. Description of HEMP hardening concepts.

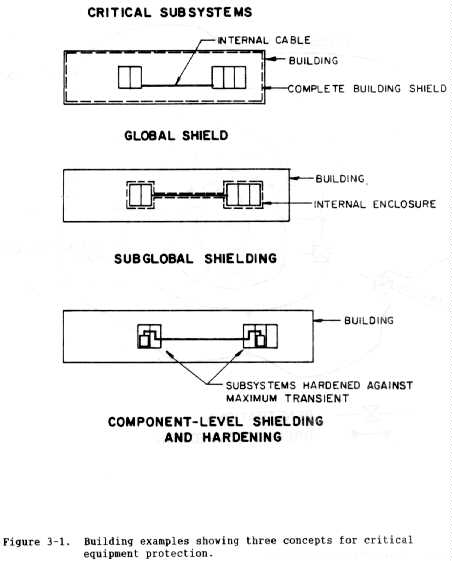

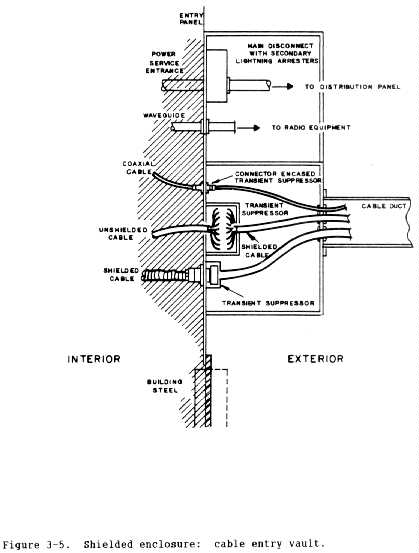

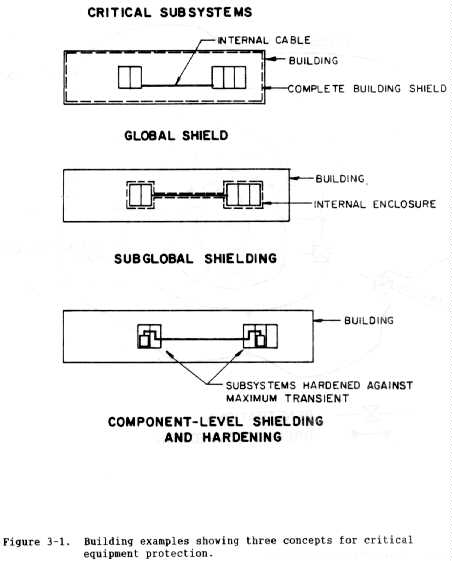

a. Shielding. For HEMP-hardened facilities, some kind of EM shielding is

essential. Shielding theory is discussed in detail in chapter 5 and is

treated thoroughly in the literature. Shielding involves the use of a barrier

or series of barriers to reduce the magnitude of the EM energy incident upon

the electronic or electrical system to be protected. Shielding philosophy can

be developed around different approaches as discussed in paragraphs (1)

through (6) below and shown in figure 3-1.

(1) Global shielding. Global shielding (or hardening) is a protection

concept that uses an overall shield to encompass the entire facility. In this

approach, all conducting penetrations and all apertures are protected at the

shield. The intent is to keep all HEMP fields and HEMP-induced transients

outside the protected volume. The global shield could be placed on the entire

outer walls, ceiling, and floor (surface) of the facility, or it could be

reduced to a smaller volume that contains all sensitive equipment to be

protected. The most common shield material for global shielding of ground-

based facilities is sheet steel with welded seams, although other designs can

provide adequate global HEMP shielding.

(a) Global shielding may be desirable if there is a requirement to

be able to modify, reorganize, add to, or move the sensitive equipment without

changing the shield or protective features.

(b) A remote, yet possible, disadvantage of global shielding that

must be considered is that a single protective component or device failure may

jeopardize the entire facility.

(2) Tailored shielding. Tailored shielding is a protection concept in

which shielding is designed and constructed according to specific protection

requirements for the equipment involved. After defining the system to be

protected, its possible operating configurations, the expected HEMP

environment, coupling paths, equipment sensitivities, and subsystem/system

criticalities, the required protection levels for various subsystems or groups

of subsystems can be defined. Tradeoff studies may be performed for comparing

various shielding arrangements to verify that they meet safety margins in

protection, cost-effectiveness, maintainability, survivability, flexibility,

and other requirements. The objective is to optimize protection for the

specific mission-critical system. Tailored shielding options may include

global shielding, zonal shielding (discussed under (3) below), shielding of

cabinets or components, or combinations thereof. In a typical tailored

protection design, discrete protection will be provided to eliminate specific,

localized deficiencies.

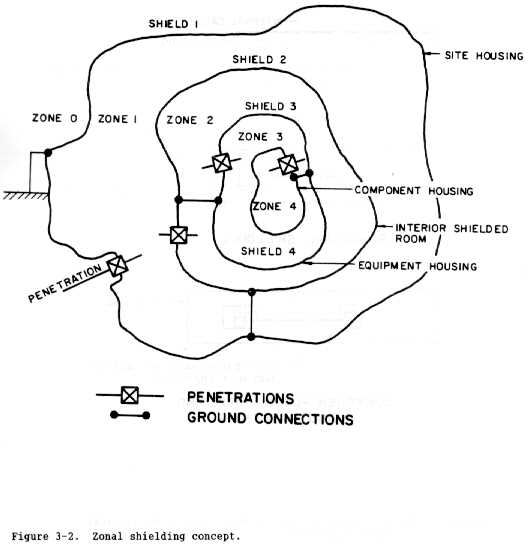

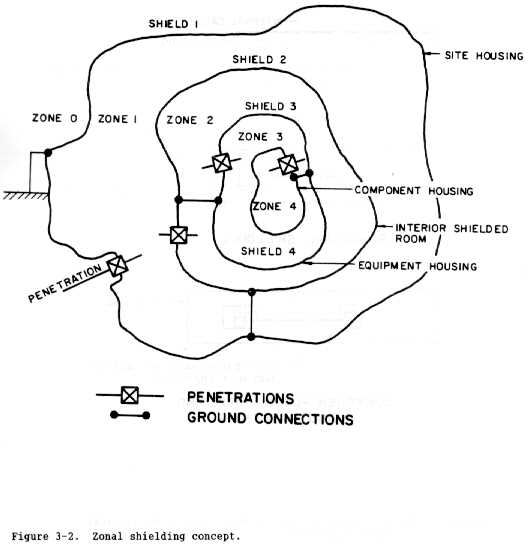

(3) Zonal or topological shielding. Zonal or topological shielding

(ref 3-1) is a concept in which a facility is divided into zones, with

shielding barriers located topologically in a shield within a shield

configuration. Figure 3-2 shows a generic topological shielding system. The

outer zone is designated zone 0; zone 1 is inside shield 1 but outside shield

2. Zones and shields are assigned increasingly larger numbers as they

progress toward the more deeply nested areas.

(1) Global shielding. Global shielding (or hardening) is a protection

concept that uses an overall shield to encompass the entire facility. In this

approach, all conducting penetrations and all apertures are protected at the

shield. The intent is to keep all HEMP fields and HEMP-induced transients

outside the protected volume. The global shield could be placed on the entire

outer walls, ceiling, and floor (surface) of the facility, or it could be

reduced to a smaller volume that contains all sensitive equipment to be

protected. The most common shield material for global shielding of ground-

based facilities is sheet steel with welded seams, although other designs can

provide adequate global HEMP shielding.

(a) Global shielding may be desirable if there is a requirement to

be able to modify, reorganize, add to, or move the sensitive equipment without

changing the shield or protective features.

(b) A remote, yet possible, disadvantage of global shielding that

must be considered is that a single protective component or device failure may

jeopardize the entire facility.

(2) Tailored shielding. Tailored shielding is a protection concept in

which shielding is designed and constructed according to specific protection

requirements for the equipment involved. After defining the system to be

protected, its possible operating configurations, the expected HEMP

environment, coupling paths, equipment sensitivities, and subsystem/system

criticalities, the required protection levels for various subsystems or groups

of subsystems can be defined. Tradeoff studies may be performed for comparing

various shielding arrangements to verify that they meet safety margins in

protection, cost-effectiveness, maintainability, survivability, flexibility,

and other requirements. The objective is to optimize protection for the

specific mission-critical system. Tailored shielding options may include

global shielding, zonal shielding (discussed under (3) below), shielding of

cabinets or components, or combinations thereof. In a typical tailored

protection design, discrete protection will be provided to eliminate specific,

localized deficiencies.

(3) Zonal or topological shielding. Zonal or topological shielding

(ref 3-1) is a concept in which a facility is divided into zones, with

shielding barriers located topologically in a shield within a shield

configuration. Figure 3-2 shows a generic topological shielding system. The

outer zone is designated zone 0; zone 1 is inside shield 1 but outside shield

2. Zones and shields are assigned increasingly larger numbers as they

progress toward the more deeply nested areas.

(a) Note that figure 3-2 is a simple schematic to represent the

zoning concept; although not depicted, each zone could contain more sets of

subzones. For example, shield 3 could contain 2 or more zones designated as

zone 4. Further, figure 3-2 shows possible shield types including a site

housing shield and an interior shielded room, with equipment and component

housings making up the shields of the next topological orders.

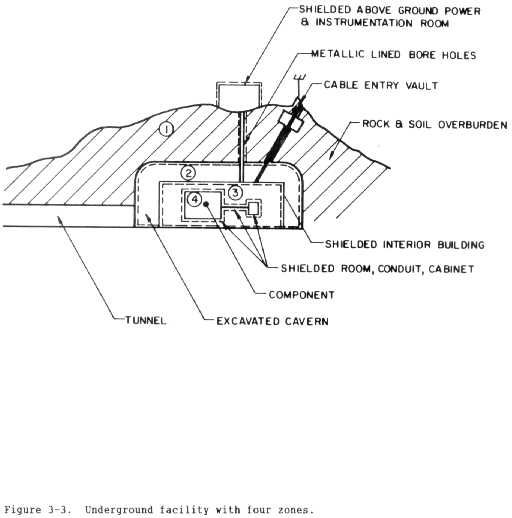

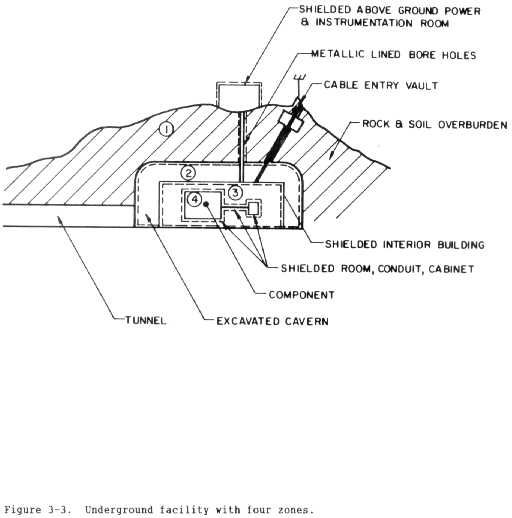

(b) The zonal concept shown in figure 3-3 is a specific example of

an underground facility that uses topologically zoned protection. The rock

and soil overburden above the facility serves as shield 1. Zone 1 is the

volume between the underground building and the excavated outline of overhead

rock. In some cases, a shield of this type provides adequate protection for

robust electrical or electronic equipment. Shield 2 is composed of a sheet

metal building that may provide only a limited level of shielding. Inside

this building (zone 2), some systems would be adequately protected. The

above-ground building and connecting conduit represent an extension of zone 2.

Shield 3 is then the interior shielded room which provides further protection

within zone 3. where sensitive, electronic equipment may be operated.

(a) Note that figure 3-2 is a simple schematic to represent the

zoning concept; although not depicted, each zone could contain more sets of

subzones. For example, shield 3 could contain 2 or more zones designated as

zone 4. Further, figure 3-2 shows possible shield types including a site

housing shield and an interior shielded room, with equipment and component

housings making up the shields of the next topological orders.

(b) The zonal concept shown in figure 3-3 is a specific example of

an underground facility that uses topologically zoned protection. The rock

and soil overburden above the facility serves as shield 1. Zone 1 is the

volume between the underground building and the excavated outline of overhead

rock. In some cases, a shield of this type provides adequate protection for

robust electrical or electronic equipment. Shield 2 is composed of a sheet

metal building that may provide only a limited level of shielding. Inside

this building (zone 2), some systems would be adequately protected. The

above-ground building and connecting conduit represent an extension of zone 2.

Shield 3 is then the interior shielded room which provides further protection

within zone 3. where sensitive, electronic equipment may be operated.

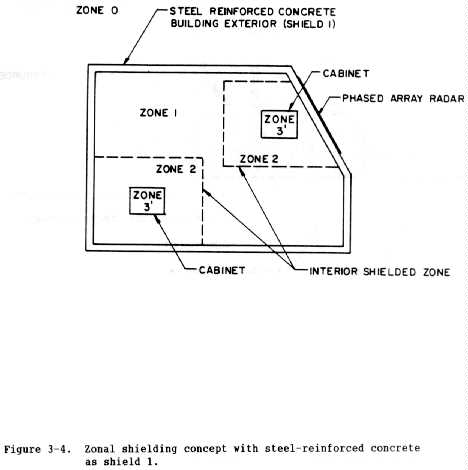

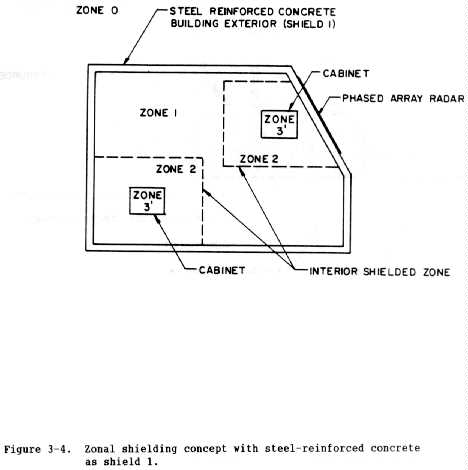

(c) Figure 3-4 shows another specific example of a zonal or

topographically shielded facility for which steel-reinforced concrete

comprises shield 1. This type of shield usually does not provide adequate

protection and thus the additional shields are necessary.

(c) Figure 3-4 shows another specific example of a zonal or

topographically shielded facility for which steel-reinforced concrete

comprises shield 1. This type of shield usually does not provide adequate

protection and thus the additional shields are necessary.

(4) System configuration. The term "system configuration" identifies

which way the cables, wires, equipment, and subsystems are laid out in

relationship to each other, as well as the relationship of these items to the

topological boundaries. In some instances, the cables, connectors, and

equipment casings are actually part of the topological protection. Although

"system configuration" as defined does not directly attenuate the environment,

it is an important element in the topological protection concept. The system

configuration influences protection design requirements since some

configurations are easier to protect than others ~e.g., collocation of all

mission-critical equipment). Thus, the system configuration should be

coordinated with the protection design and the protection topology will be

optimal for a specific configuration. During the facility life cycle, the

protection design may be required to accommodate some changes in

configuration. To ensure that the configuration's design modifications do not

compromise or defeat the protection, careful configuration management is

necessary. The topology should be designed to tolerate configuration changes

that are totally within a boundary. The boundary can never be violated (for

example, opened)--only extended. All modifications must be subjected to

review by EMP experts to ensure continual compliance with the HEMP hardening

requirements.

(5) Cable shielding. Conductive or metallic cable shielding or conduit

is used in the zonal/topological protection concept to extend the boundary

formed by equipment enclosures and thus provide a way to interconnect elements

while maintaining boundary continuity. Cable shielding is also used to

protect a wire or wires as they travel from one boundary to another. This

would be the case with a shielded RF signal traveling from its entrance into a

building to the RF receiver. From a HEMP standpoint, the shielding attenuates

coupling of radiated energy within the first boundary as the signal travels to

the receiver. Of course the shield is somewhat reciprocal in that it also

prevents signals from radiating out of the cable. The main feature of cable

shielding stressed here is continuity of the boundary provided by the cable

shield/connector combination which may require special joints.

(a) Another way to maintain this continuity and provide cable

shielding is by using steel conduit to house all wires and cables. The steel

conduit will provide substantially higher shielding levels than the cable

shields. Chapter 5 presents conduit system design in detail.

(b) Both cable shields and conduit connected to a shielded zone must

have equal or greater shielding effectiveness than the shield.

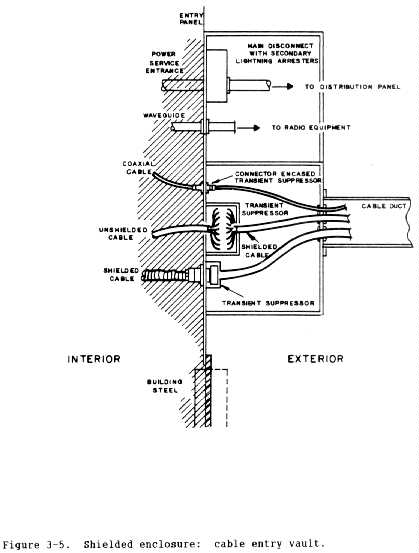

(c) Figure 3-5 shows a cable entry vault used to protect cable

penetrations through a shield. Entry vaults are discussed under shield

penetrations in paragraph c below.

(4) System configuration. The term "system configuration" identifies

which way the cables, wires, equipment, and subsystems are laid out in

relationship to each other, as well as the relationship of these items to the

topological boundaries. In some instances, the cables, connectors, and

equipment casings are actually part of the topological protection. Although

"system configuration" as defined does not directly attenuate the environment,

it is an important element in the topological protection concept. The system

configuration influences protection design requirements since some

configurations are easier to protect than others ~e.g., collocation of all

mission-critical equipment). Thus, the system configuration should be

coordinated with the protection design and the protection topology will be

optimal for a specific configuration. During the facility life cycle, the

protection design may be required to accommodate some changes in

configuration. To ensure that the configuration's design modifications do not

compromise or defeat the protection, careful configuration management is

necessary. The topology should be designed to tolerate configuration changes

that are totally within a boundary. The boundary can never be violated (for

example, opened)--only extended. All modifications must be subjected to

review by EMP experts to ensure continual compliance with the HEMP hardening

requirements.

(5) Cable shielding. Conductive or metallic cable shielding or conduit

is used in the zonal/topological protection concept to extend the boundary

formed by equipment enclosures and thus provide a way to interconnect elements

while maintaining boundary continuity. Cable shielding is also used to

protect a wire or wires as they travel from one boundary to another. This

would be the case with a shielded RF signal traveling from its entrance into a

building to the RF receiver. From a HEMP standpoint, the shielding attenuates

coupling of radiated energy within the first boundary as the signal travels to

the receiver. Of course the shield is somewhat reciprocal in that it also

prevents signals from radiating out of the cable. The main feature of cable

shielding stressed here is continuity of the boundary provided by the cable

shield/connector combination which may require special joints.

(a) Another way to maintain this continuity and provide cable

shielding is by using steel conduit to house all wires and cables. The steel

conduit will provide substantially higher shielding levels than the cable

shields. Chapter 5 presents conduit system design in detail.

(b) Both cable shields and conduit connected to a shielded zone must

have equal or greater shielding effectiveness than the shield.

(c) Figure 3-5 shows a cable entry vault used to protect cable

penetrations through a shield. Entry vaults are discussed under shield

penetrations in paragraph c below.

(6) Grounding. Some form of grounding is required in any electrical or

electronic system for protecting personnel from electrical shock, controlling

interference, proper shunting of transient currents around sensitive

electronics, and other reasons. (Grounding does not directly provide

protection against EMP, but must be done properly to prevent creation of more

serious EMP vulnerabilities.) Ideally, grounding would keep all system

components at a common potential. In practice, because of possible inductive

loops, capacitive coupling, line and bonding impedances, antenna ringing

effects, and other phenomena, large potentials may exist on grounding

circuits. The choice of grounding concept is therefore important in the HEMP

protection philosophy.

b. Hardening allocation concept. The shielding concepts in this chapter

introduce the concept of hardening allocation in which the overall protection

philosophy specifies degrees of hardening for each zone. The practicality of

this concept usually depends on the complexity of the system to be protected.

If it is determined that an overall SE of 80 decibels is required for the most

sensitive components, but the remaining elements require only 60 decibels,

then zones with different SE may be established. The cost-effectiveness of a

zonal design with a hardening allocation for each barrier must be studied

carefully on a facility/ system specific basis to determine the practicality

of this approach.

c. Shield penetration protection concepts. All shielded zones will

require penetrations to allow entry of equipment, personnel, electric power,

communications, and control signals, ventilation, water, fuel, and various

fluids. Without Protection, these penetrations compromise the shield.

(l) Large access doors. Large access doors are often necessary to

provide an entry for equipment, supplies, or vehicles into EMP hardened

facilities. In facilities that require blast overpressure protection, large

blast doors are used. These doors generally use one or more thick steel

plates to provide protection. The door's inherent shielding ability is thus

high, but its large size presents a difficult gasketing problem. If blast

protection is not required, it is still necessary to design the door with a

high degree of structural strength. This step is to ensure that the door can

provide the necessary gasket compression force and that proper mechanical

alignment of closure contact surfaces is maintained.

(2) Personnel entrances. Two concepts are commonly used for personnel

entrances: conventional EMP/RFI shielded doors and personnel tunnels that act

as waveguides below cutoff. The shielded doors generally use metal

fingerstock or EMI/RFI gaskets to provide an electromagnetic seal around the

door jamb periphery. Currently available gasket and fingerstock doors require

regularly scheduled maintenance and/or replacement to maintain required

shielding levels. The gaskets are relatively easily damaged and also require

replacement. Air-expandable doors may also be used, although they typically

have more maintenance problems. These doors generally use a movable

subassembly of two shielding plates on a framework that is moved on rollers in

and out of a steel-framed opening. When closed, air expansion tubes cause the

two shielding plates to make uniform surface contact with the frame inner

surfaces.

(a) Fingerstock doors can provide over 80 decibels of shielding to

magnetic fields from 100 kilohertz through 30 megahertz and greater SE to

plane waves and electric fields. Air-expandable doors can provide greater

than 120 decibels of magnetic field SE from 10 kilohertz to 10 gigahertz.

(b) Air-expandable doors require an air source and air controls with

back-up in safety controls. They also require very strong steel frames and,

as a result, are more expensive than gasketed doors. They are also more

difficult and costly to maintain. The air-expandable door would thus be used

only when a large safety margin of HEMP shielding is needed or when equipment

to be protected is extremely sensitive to HEMP or other EM interference.

(c) The waveguide entry tunnel acts as a WBC that will typically

have a cutoff frequency* in the 60-megahertz region. Thus, the higher

frequencies in the HEMP spectrum will penetrate it. Doors are therefore

required to prevent the higher frequency signals from penetrating. Since only

high frequencies can propagate through, doors have good attenuation in this

range and can easily provide the required attenuation. Maintenance require-

ments are not as stringent as for doors that must block the entire frequency

spectrum; thus, the waveguide entry tunnel for personnel access is attractive

from a life-cycle cost standpoint. When the facility has a TEMPEST

requirement as well as EMP shielding requirements, the tunnel is usually

designed with interlocking doors, i.e., a door at each end and interlocked so

that only one door can be opened at once, thus preventing any leakage of

classified information during the entry of personnel. The waveguide entry

tunnel also is highly useful in underground or buried facilities because the

overburden attenuates the high frequencies, thus acting to complement the

tunnel attentuation.

________________________

*Cutoff frequency is determined by the relationship Fo = 5900 MHz/W, where W is

the greatest cross sectional dimension in inches. Below cutoff, the waveguide

attenuation is a function of the waveguide length. In practice, the length-to-

width ratio should be 5.

(3) Electrical penetrations. A common feature for electrical

penetrations in a global protection approach is a cable entry vault to prevent

large currents on external conductors from being conducted into the facility.

Ideally, all penetrations should enter a single vault. In some cases,

however, it may be necessary to separate the vault into two compartments or to

use two vaults for penetrations by different types of lines: power, signal

and control, and antenna. The vault must be connected directly to the

external facility ground system. (See chapter 5 for details.) The cable

entry vault serves three purposes: to insure that penetrating conductors do

not cause conducted HEMP energy to enter the protected topology; to contain

and divert penetrator-conducted HEMP energy to the boundary exterior; and to

contain or divert radiant EM energy resulting from the activation of transient

suppression devices subjected to a conducted pulse. Conductive penetrations,

such as a conduit, waveguide, or shielded cable, must have a circumferential

weld or other means of providing good electrical connection at the

intersection with the entry vault.

(4) Transient suppression devices and filters. Transient suppression

devices fill a critical gap in the concept of topological protection. The

necessity of supplying power to a facility and of communicating over cables or

antennas are two major factors contributing to their use. Power lines

entering a facility are typically connected to an unshielded power grid so

that large, conducted currents must be bled off to prevent their entry into a

facility.* These currents are diverted to the exterior boundary of the

topology. This boundary can be an overall external shield or an enclosed en-

trance vault. Antennas, such as for high-frequency (HF) communications, are

designed to gather EM signals (at wavelengths in the EMP frequency spectrum)

and to apply these signals to the center conductor of a shielded cable. The

EMP transients associated with an HF antenna can be, by far, the largest

single signal entering a facility. Transient suppressors often are used in

conjunction with filters. Filters are frequency-selective whereas surge

suppressors are amplitude-selective. Filters often are used to attenuate

transients associated with the nonlinear operation of surge arresters. They

also are used for selectively passing (or stopping) frequency bands as in the

case of antenna cable penetrations. Transient suppressors are an integral

part of the EM topology, demanding specific installation techniques as will be

seen later. A spark gap is a surge suppressor that provides a conducting path

to ground when the voltage across the device exceeds the gap breakdown level.

Spark gaps with a high current capacity do not operate quickly enough to block

all HEMP energy transients entering the vault. For this reason, it may be

necessary to use other protection devices in conjunction with the spark gap.

________________________

*Within a facility, inside shield 1, power lines are often

routed through steel conduits to provide shielding.

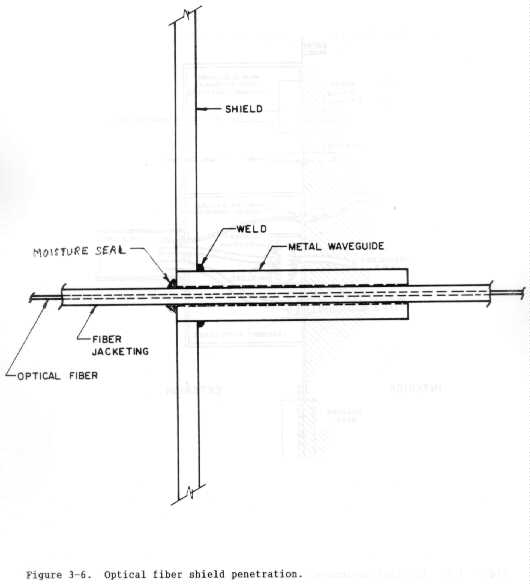

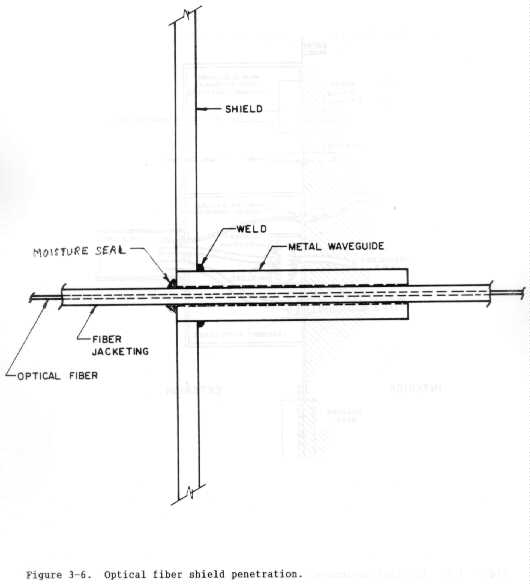

(5) Electromagnetic isolation. The electromagnetic isolation concept

involves the use of elements either immune to interaction with EM radiation or

that provide a current path interruption. Optical fibers are examples of

elements immune to EM radiation that can be used to reduce the number of

conductive penetrations. For practical purposes, optical fibers can be used

for long communications links without signal interference from HEMP. Further,

they can be used to enter shielded zones through waveguide below cutoff

penetrations without compromising the EM shielding effectiveness, as figure 3-

6 shows. Where possible, optical fibers are recommended for--

(a) Voice and data communications lines.

(b) Energy monitoring and control systems (EMCS).

(c) Intrusion detection systems.

(d) Other security systems.

(e) Control systems.

(f) Any other use where possible and practical.

(6) Grounding. Some form of grounding is required in any electrical or

electronic system for protecting personnel from electrical shock, controlling

interference, proper shunting of transient currents around sensitive

electronics, and other reasons. (Grounding does not directly provide

protection against EMP, but must be done properly to prevent creation of more

serious EMP vulnerabilities.) Ideally, grounding would keep all system

components at a common potential. In practice, because of possible inductive

loops, capacitive coupling, line and bonding impedances, antenna ringing

effects, and other phenomena, large potentials may exist on grounding

circuits. The choice of grounding concept is therefore important in the HEMP

protection philosophy.

b. Hardening allocation concept. The shielding concepts in this chapter

introduce the concept of hardening allocation in which the overall protection

philosophy specifies degrees of hardening for each zone. The practicality of

this concept usually depends on the complexity of the system to be protected.

If it is determined that an overall SE of 80 decibels is required for the most

sensitive components, but the remaining elements require only 60 decibels,

then zones with different SE may be established. The cost-effectiveness of a

zonal design with a hardening allocation for each barrier must be studied

carefully on a facility/ system specific basis to determine the practicality

of this approach.

c. Shield penetration protection concepts. All shielded zones will

require penetrations to allow entry of equipment, personnel, electric power,

communications, and control signals, ventilation, water, fuel, and various

fluids. Without Protection, these penetrations compromise the shield.

(l) Large access doors. Large access doors are often necessary to

provide an entry for equipment, supplies, or vehicles into EMP hardened

facilities. In facilities that require blast overpressure protection, large

blast doors are used. These doors generally use one or more thick steel

plates to provide protection. The door's inherent shielding ability is thus

high, but its large size presents a difficult gasketing problem. If blast

protection is not required, it is still necessary to design the door with a

high degree of structural strength. This step is to ensure that the door can

provide the necessary gasket compression force and that proper mechanical

alignment of closure contact surfaces is maintained.

(2) Personnel entrances. Two concepts are commonly used for personnel

entrances: conventional EMP/RFI shielded doors and personnel tunnels that act

as waveguides below cutoff. The shielded doors generally use metal

fingerstock or EMI/RFI gaskets to provide an electromagnetic seal around the

door jamb periphery. Currently available gasket and fingerstock doors require

regularly scheduled maintenance and/or replacement to maintain required

shielding levels. The gaskets are relatively easily damaged and also require

replacement. Air-expandable doors may also be used, although they typically

have more maintenance problems. These doors generally use a movable

subassembly of two shielding plates on a framework that is moved on rollers in

and out of a steel-framed opening. When closed, air expansion tubes cause the

two shielding plates to make uniform surface contact with the frame inner

surfaces.

(a) Fingerstock doors can provide over 80 decibels of shielding to

magnetic fields from 100 kilohertz through 30 megahertz and greater SE to

plane waves and electric fields. Air-expandable doors can provide greater

than 120 decibels of magnetic field SE from 10 kilohertz to 10 gigahertz.

(b) Air-expandable doors require an air source and air controls with

back-up in safety controls. They also require very strong steel frames and,

as a result, are more expensive than gasketed doors. They are also more

difficult and costly to maintain. The air-expandable door would thus be used

only when a large safety margin of HEMP shielding is needed or when equipment

to be protected is extremely sensitive to HEMP or other EM interference.

(c) The waveguide entry tunnel acts as a WBC that will typically

have a cutoff frequency* in the 60-megahertz region. Thus, the higher

frequencies in the HEMP spectrum will penetrate it. Doors are therefore

required to prevent the higher frequency signals from penetrating. Since only

high frequencies can propagate through, doors have good attenuation in this

range and can easily provide the required attenuation. Maintenance require-

ments are not as stringent as for doors that must block the entire frequency

spectrum; thus, the waveguide entry tunnel for personnel access is attractive

from a life-cycle cost standpoint. When the facility has a TEMPEST

requirement as well as EMP shielding requirements, the tunnel is usually

designed with interlocking doors, i.e., a door at each end and interlocked so

that only one door can be opened at once, thus preventing any leakage of

classified information during the entry of personnel. The waveguide entry

tunnel also is highly useful in underground or buried facilities because the

overburden attenuates the high frequencies, thus acting to complement the

tunnel attentuation.

________________________

*Cutoff frequency is determined by the relationship Fo = 5900 MHz/W, where W is

the greatest cross sectional dimension in inches. Below cutoff, the waveguide

attenuation is a function of the waveguide length. In practice, the length-to-

width ratio should be 5.

(3) Electrical penetrations. A common feature for electrical

penetrations in a global protection approach is a cable entry vault to prevent

large currents on external conductors from being conducted into the facility.

Ideally, all penetrations should enter a single vault. In some cases,

however, it may be necessary to separate the vault into two compartments or to

use two vaults for penetrations by different types of lines: power, signal

and control, and antenna. The vault must be connected directly to the

external facility ground system. (See chapter 5 for details.) The cable

entry vault serves three purposes: to insure that penetrating conductors do

not cause conducted HEMP energy to enter the protected topology; to contain

and divert penetrator-conducted HEMP energy to the boundary exterior; and to

contain or divert radiant EM energy resulting from the activation of transient

suppression devices subjected to a conducted pulse. Conductive penetrations,

such as a conduit, waveguide, or shielded cable, must have a circumferential

weld or other means of providing good electrical connection at the

intersection with the entry vault.

(4) Transient suppression devices and filters. Transient suppression

devices fill a critical gap in the concept of topological protection. The

necessity of supplying power to a facility and of communicating over cables or

antennas are two major factors contributing to their use. Power lines

entering a facility are typically connected to an unshielded power grid so

that large, conducted currents must be bled off to prevent their entry into a

facility.* These currents are diverted to the exterior boundary of the

topology. This boundary can be an overall external shield or an enclosed en-

trance vault. Antennas, such as for high-frequency (HF) communications, are

designed to gather EM signals (at wavelengths in the EMP frequency spectrum)

and to apply these signals to the center conductor of a shielded cable. The

EMP transients associated with an HF antenna can be, by far, the largest

single signal entering a facility. Transient suppressors often are used in

conjunction with filters. Filters are frequency-selective whereas surge

suppressors are amplitude-selective. Filters often are used to attenuate

transients associated with the nonlinear operation of surge arresters. They

also are used for selectively passing (or stopping) frequency bands as in the

case of antenna cable penetrations. Transient suppressors are an integral

part of the EM topology, demanding specific installation techniques as will be

seen later. A spark gap is a surge suppressor that provides a conducting path

to ground when the voltage across the device exceeds the gap breakdown level.

Spark gaps with a high current capacity do not operate quickly enough to block

all HEMP energy transients entering the vault. For this reason, it may be

necessary to use other protection devices in conjunction with the spark gap.

________________________

*Within a facility, inside shield 1, power lines are often

routed through steel conduits to provide shielding.

(5) Electromagnetic isolation. The electromagnetic isolation concept

involves the use of elements either immune to interaction with EM radiation or

that provide a current path interruption. Optical fibers are examples of

elements immune to EM radiation that can be used to reduce the number of

conductive penetrations. For practical purposes, optical fibers can be used

for long communications links without signal interference from HEMP. Further,

they can be used to enter shielded zones through waveguide below cutoff

penetrations without compromising the EM shielding effectiveness, as figure 3-

6 shows. Where possible, optical fibers are recommended for--

(a) Voice and data communications lines.

(b) Energy monitoring and control systems (EMCS).

(c) Intrusion detection systems.

(d) Other security systems.

(e) Control systems.

(f) Any other use where possible and practical.

(6) Dielectric isolation. Other isolation techniques include using

dielectric isolators for shield penetration when external metallic EM energy

collectors are involved. Examples are control rods* or cables (normally

metallic), piping systems for fluids, and metallic duct systems for air.

Dielectric sections are installed at or near the shield to prevent the energy

induced on the external metallic part from being conducted through the shield.

Dielectric control rods can enter through a shield in the same way as optical

fibers, that is, through a waveguide-below-cutoff section. Dielectric isola-

tion concepts for metallic piping systems and air ducts are discussed in

chapter 5.

_________________________

* Rods that must be mechanically rotated or pulled to control switches, valves,

and other components.

(7) Isolation switching. Although not recommended now, isolation

switching has been provided at facilities so they can use commercial electric

power during routine operation, but can switch to internal generators or power

systems in the event of an emergency such as nuclear attack. Since the

commercial power wiring is a source of significant HEMP energy injection

through a shield, switching to internally generated power is an obvious

advantage when advance warning of impending nuclear attack is received and

throughout the entire nuclear attack cycle. This concept applies to

communications lines and control lines as well as power lines. Switching used

in past facility designs has been called "alert attack" switching. Such

switching must provide adequate switch contact separation to prevent arcing,

and must be designed to reduce coupling interactions between wiring and switch

contacts to acceptable levels. It should be noted that advance notice of a

HEMP attack is not always provided.

3-4. Cited reference.

3-1. Vance, E. F., Shielding and Grounding Topology for Interference

Control, Interaction Note 306 (Air Force Weapons Laboratory

[AFWL], APril 1977).

3-5. Uncited references.

Bailey, D. T., et al., EMP Hardening Guidelines: System Life Cycle

Cost Design Considerations, AWFL-TR-79-161 (AWFL, May 1980).

BDM Corporation, Defense Nuclear Agency (DNA) EMP Course (Draft),

BDM/W-82-305-TR (DNA, April 1983).

Mindel, I. N., DNA EMP Awareness Course Notes, Third Edition, DNA

2772T (October 1977).

------------------------------------------------------------------------------

[End Chapter 3]

(6) Dielectric isolation. Other isolation techniques include using

dielectric isolators for shield penetration when external metallic EM energy

collectors are involved. Examples are control rods* or cables (normally

metallic), piping systems for fluids, and metallic duct systems for air.

Dielectric sections are installed at or near the shield to prevent the energy

induced on the external metallic part from being conducted through the shield.

Dielectric control rods can enter through a shield in the same way as optical

fibers, that is, through a waveguide-below-cutoff section. Dielectric isola-

tion concepts for metallic piping systems and air ducts are discussed in

chapter 5.

_________________________

* Rods that must be mechanically rotated or pulled to control switches, valves,

and other components.

(7) Isolation switching. Although not recommended now, isolation

switching has been provided at facilities so they can use commercial electric

power during routine operation, but can switch to internal generators or power

systems in the event of an emergency such as nuclear attack. Since the

commercial power wiring is a source of significant HEMP energy injection

through a shield, switching to internally generated power is an obvious

advantage when advance warning of impending nuclear attack is received and

throughout the entire nuclear attack cycle. This concept applies to

communications lines and control lines as well as power lines. Switching used

in past facility designs has been called "alert attack" switching. Such

switching must provide adequate switch contact separation to prevent arcing,

and must be designed to reduce coupling interactions between wiring and switch

contacts to acceptable levels. It should be noted that advance notice of a

HEMP attack is not always provided.

3-4. Cited reference.

3-1. Vance, E. F., Shielding and Grounding Topology for Interference

Control, Interaction Note 306 (Air Force Weapons Laboratory

[AFWL], APril 1977).

3-5. Uncited references.

Bailey, D. T., et al., EMP Hardening Guidelines: System Life Cycle

Cost Design Considerations, AWFL-TR-79-161 (AWFL, May 1980).

BDM Corporation, Defense Nuclear Agency (DNA) EMP Course (Draft),

BDM/W-82-305-TR (DNA, April 1983).

Mindel, I. N., DNA EMP Awareness Course Notes, Third Edition, DNA

2772T (October 1977).

------------------------------------------------------------------------------

[End Chapter 3]

(1) Global shielding. Global shielding (or hardening) is a protection

concept that uses an overall shield to encompass the entire facility. In this

approach, all conducting penetrations and all apertures are protected at the

shield. The intent is to keep all HEMP fields and HEMP-induced transients

outside the protected volume. The global shield could be placed on the entire

outer walls, ceiling, and floor (surface) of the facility, or it could be

reduced to a smaller volume that contains all sensitive equipment to be

protected. The most common shield material for global shielding of ground-

based facilities is sheet steel with welded seams, although other designs can

provide adequate global HEMP shielding.

(a) Global shielding may be desirable if there is a requirement to

be able to modify, reorganize, add to, or move the sensitive equipment without

changing the shield or protective features.

(b) A remote, yet possible, disadvantage of global shielding that

must be considered is that a single protective component or device failure may

jeopardize the entire facility.

(2) Tailored shielding. Tailored shielding is a protection concept in

which shielding is designed and constructed according to specific protection

requirements for the equipment involved. After defining the system to be

protected, its possible operating configurations, the expected HEMP

environment, coupling paths, equipment sensitivities, and subsystem/system

criticalities, the required protection levels for various subsystems or groups

of subsystems can be defined. Tradeoff studies may be performed for comparing

various shielding arrangements to verify that they meet safety margins in

protection, cost-effectiveness, maintainability, survivability, flexibility,

and other requirements. The objective is to optimize protection for the

specific mission-critical system. Tailored shielding options may include

global shielding, zonal shielding (discussed under (3) below), shielding of

cabinets or components, or combinations thereof. In a typical tailored

protection design, discrete protection will be provided to eliminate specific,

localized deficiencies.

(3) Zonal or topological shielding. Zonal or topological shielding

(ref 3-1) is a concept in which a facility is divided into zones, with

shielding barriers located topologically in a shield within a shield

configuration. Figure 3-2 shows a generic topological shielding system. The

outer zone is designated zone 0; zone 1 is inside shield 1 but outside shield

2. Zones and shields are assigned increasingly larger numbers as they

progress toward the more deeply nested areas.

(1) Global shielding. Global shielding (or hardening) is a protection

concept that uses an overall shield to encompass the entire facility. In this

approach, all conducting penetrations and all apertures are protected at the

shield. The intent is to keep all HEMP fields and HEMP-induced transients

outside the protected volume. The global shield could be placed on the entire

outer walls, ceiling, and floor (surface) of the facility, or it could be

reduced to a smaller volume that contains all sensitive equipment to be

protected. The most common shield material for global shielding of ground-

based facilities is sheet steel with welded seams, although other designs can

provide adequate global HEMP shielding.

(a) Global shielding may be desirable if there is a requirement to

be able to modify, reorganize, add to, or move the sensitive equipment without

changing the shield or protective features.

(b) A remote, yet possible, disadvantage of global shielding that

must be considered is that a single protective component or device failure may

jeopardize the entire facility.

(2) Tailored shielding. Tailored shielding is a protection concept in

which shielding is designed and constructed according to specific protection

requirements for the equipment involved. After defining the system to be

protected, its possible operating configurations, the expected HEMP

environment, coupling paths, equipment sensitivities, and subsystem/system

criticalities, the required protection levels for various subsystems or groups

of subsystems can be defined. Tradeoff studies may be performed for comparing

various shielding arrangements to verify that they meet safety margins in

protection, cost-effectiveness, maintainability, survivability, flexibility,

and other requirements. The objective is to optimize protection for the

specific mission-critical system. Tailored shielding options may include

global shielding, zonal shielding (discussed under (3) below), shielding of

cabinets or components, or combinations thereof. In a typical tailored

protection design, discrete protection will be provided to eliminate specific,

localized deficiencies.

(3) Zonal or topological shielding. Zonal or topological shielding

(ref 3-1) is a concept in which a facility is divided into zones, with

shielding barriers located topologically in a shield within a shield

configuration. Figure 3-2 shows a generic topological shielding system. The

outer zone is designated zone 0; zone 1 is inside shield 1 but outside shield

2. Zones and shields are assigned increasingly larger numbers as they

progress toward the more deeply nested areas.

(a) Note that figure 3-2 is a simple schematic to represent the

zoning concept; although not depicted, each zone could contain more sets of

subzones. For example, shield 3 could contain 2 or more zones designated as

zone 4. Further, figure 3-2 shows possible shield types including a site

housing shield and an interior shielded room, with equipment and component

housings making up the shields of the next topological orders.

(b) The zonal concept shown in figure 3-3 is a specific example of

an underground facility that uses topologically zoned protection. The rock

and soil overburden above the facility serves as shield 1. Zone 1 is the

volume between the underground building and the excavated outline of overhead

rock. In some cases, a shield of this type provides adequate protection for

robust electrical or electronic equipment. Shield 2 is composed of a sheet

metal building that may provide only a limited level of shielding. Inside

this building (zone 2), some systems would be adequately protected. The

above-ground building and connecting conduit represent an extension of zone 2.

Shield 3 is then the interior shielded room which provides further protection

within zone 3. where sensitive, electronic equipment may be operated.

(a) Note that figure 3-2 is a simple schematic to represent the

zoning concept; although not depicted, each zone could contain more sets of

subzones. For example, shield 3 could contain 2 or more zones designated as

zone 4. Further, figure 3-2 shows possible shield types including a site

housing shield and an interior shielded room, with equipment and component

housings making up the shields of the next topological orders.

(b) The zonal concept shown in figure 3-3 is a specific example of

an underground facility that uses topologically zoned protection. The rock

and soil overburden above the facility serves as shield 1. Zone 1 is the

volume between the underground building and the excavated outline of overhead

rock. In some cases, a shield of this type provides adequate protection for

robust electrical or electronic equipment. Shield 2 is composed of a sheet

metal building that may provide only a limited level of shielding. Inside

this building (zone 2), some systems would be adequately protected. The

above-ground building and connecting conduit represent an extension of zone 2.

Shield 3 is then the interior shielded room which provides further protection

within zone 3. where sensitive, electronic equipment may be operated.

(c) Figure 3-4 shows another specific example of a zonal or

topographically shielded facility for which steel-reinforced concrete

comprises shield 1. This type of shield usually does not provide adequate

protection and thus the additional shields are necessary.

(c) Figure 3-4 shows another specific example of a zonal or

topographically shielded facility for which steel-reinforced concrete

comprises shield 1. This type of shield usually does not provide adequate

protection and thus the additional shields are necessary.

(4) System configuration. The term "system configuration" identifies

which way the cables, wires, equipment, and subsystems are laid out in

relationship to each other, as well as the relationship of these items to the

topological boundaries. In some instances, the cables, connectors, and

equipment casings are actually part of the topological protection. Although

"system configuration" as defined does not directly attenuate the environment,

it is an important element in the topological protection concept. The system

configuration influences protection design requirements since some

configurations are easier to protect than others ~e.g., collocation of all

mission-critical equipment). Thus, the system configuration should be

coordinated with the protection design and the protection topology will be

optimal for a specific configuration. During the facility life cycle, the

protection design may be required to accommodate some changes in

configuration. To ensure that the configuration's design modifications do not

compromise or defeat the protection, careful configuration management is

necessary. The topology should be designed to tolerate configuration changes

that are totally within a boundary. The boundary can never be violated (for

example, opened)--only extended. All modifications must be subjected to

review by EMP experts to ensure continual compliance with the HEMP hardening

requirements.

(5) Cable shielding. Conductive or metallic cable shielding or conduit

is used in the zonal/topological protection concept to extend the boundary

formed by equipment enclosures and thus provide a way to interconnect elements

while maintaining boundary continuity. Cable shielding is also used to

protect a wire or wires as they travel from one boundary to another. This

would be the case with a shielded RF signal traveling from its entrance into a

building to the RF receiver. From a HEMP standpoint, the shielding attenuates

coupling of radiated energy within the first boundary as the signal travels to

the receiver. Of course the shield is somewhat reciprocal in that it also

prevents signals from radiating out of the cable. The main feature of cable

shielding stressed here is continuity of the boundary provided by the cable

shield/connector combination which may require special joints.

(a) Another way to maintain this continuity and provide cable

shielding is by using steel conduit to house all wires and cables. The steel

conduit will provide substantially higher shielding levels than the cable

shields. Chapter 5 presents conduit system design in detail.

(b) Both cable shields and conduit connected to a shielded zone must

have equal or greater shielding effectiveness than the shield.

(c) Figure 3-5 shows a cable entry vault used to protect cable

penetrations through a shield. Entry vaults are discussed under shield

penetrations in paragraph c below.

(4) System configuration. The term "system configuration" identifies

which way the cables, wires, equipment, and subsystems are laid out in

relationship to each other, as well as the relationship of these items to the

topological boundaries. In some instances, the cables, connectors, and

equipment casings are actually part of the topological protection. Although

"system configuration" as defined does not directly attenuate the environment,

it is an important element in the topological protection concept. The system

configuration influences protection design requirements since some

configurations are easier to protect than others ~e.g., collocation of all

mission-critical equipment). Thus, the system configuration should be

coordinated with the protection design and the protection topology will be

optimal for a specific configuration. During the facility life cycle, the

protection design may be required to accommodate some changes in

configuration. To ensure that the configuration's design modifications do not

compromise or defeat the protection, careful configuration management is

necessary. The topology should be designed to tolerate configuration changes

that are totally within a boundary. The boundary can never be violated (for

example, opened)--only extended. All modifications must be subjected to

review by EMP experts to ensure continual compliance with the HEMP hardening

requirements.

(5) Cable shielding. Conductive or metallic cable shielding or conduit

is used in the zonal/topological protection concept to extend the boundary

formed by equipment enclosures and thus provide a way to interconnect elements

while maintaining boundary continuity. Cable shielding is also used to

protect a wire or wires as they travel from one boundary to another. This

would be the case with a shielded RF signal traveling from its entrance into a

building to the RF receiver. From a HEMP standpoint, the shielding attenuates

coupling of radiated energy within the first boundary as the signal travels to

the receiver. Of course the shield is somewhat reciprocal in that it also

prevents signals from radiating out of the cable. The main feature of cable

shielding stressed here is continuity of the boundary provided by the cable

shield/connector combination which may require special joints.

(a) Another way to maintain this continuity and provide cable

shielding is by using steel conduit to house all wires and cables. The steel

conduit will provide substantially higher shielding levels than the cable

shields. Chapter 5 presents conduit system design in detail.

(b) Both cable shields and conduit connected to a shielded zone must

have equal or greater shielding effectiveness than the shield.

(c) Figure 3-5 shows a cable entry vault used to protect cable

penetrations through a shield. Entry vaults are discussed under shield

penetrations in paragraph c below.

(6) Grounding. Some form of grounding is required in any electrical or

electronic system for protecting personnel from electrical shock, controlling

interference, proper shunting of transient currents around sensitive

electronics, and other reasons. (Grounding does not directly provide

protection against EMP, but must be done properly to prevent creation of more

serious EMP vulnerabilities.) Ideally, grounding would keep all system

components at a common potential. In practice, because of possible inductive

loops, capacitive coupling, line and bonding impedances, antenna ringing

effects, and other phenomena, large potentials may exist on grounding

circuits. The choice of grounding concept is therefore important in the HEMP

protection philosophy.

b. Hardening allocation concept. The shielding concepts in this chapter

introduce the concept of hardening allocation in which the overall protection

philosophy specifies degrees of hardening for each zone. The practicality of

this concept usually depends on the complexity of the system to be protected.

If it is determined that an overall SE of 80 decibels is required for the most

sensitive components, but the remaining elements require only 60 decibels,

then zones with different SE may be established. The cost-effectiveness of a

zonal design with a hardening allocation for each barrier must be studied

carefully on a facility/ system specific basis to determine the practicality

of this approach.

c. Shield penetration protection concepts. All shielded zones will

require penetrations to allow entry of equipment, personnel, electric power,

communications, and control signals, ventilation, water, fuel, and various

fluids. Without Protection, these penetrations compromise the shield.

(l) Large access doors. Large access doors are often necessary to

provide an entry for equipment, supplies, or vehicles into EMP hardened

facilities. In facilities that require blast overpressure protection, large

blast doors are used. These doors generally use one or more thick steel

plates to provide protection. The door's inherent shielding ability is thus

high, but its large size presents a difficult gasketing problem. If blast

protection is not required, it is still necessary to design the door with a

high degree of structural strength. This step is to ensure that the door can

provide the necessary gasket compression force and that proper mechanical

alignment of closure contact surfaces is maintained.

(2) Personnel entrances. Two concepts are commonly used for personnel

entrances: conventional EMP/RFI shielded doors and personnel tunnels that act

as waveguides below cutoff. The shielded doors generally use metal

fingerstock or EMI/RFI gaskets to provide an electromagnetic seal around the

door jamb periphery. Currently available gasket and fingerstock doors require

regularly scheduled maintenance and/or replacement to maintain required

shielding levels. The gaskets are relatively easily damaged and also require

replacement. Air-expandable doors may also be used, although they typically

have more maintenance problems. These doors generally use a movable

subassembly of two shielding plates on a framework that is moved on rollers in

and out of a steel-framed opening. When closed, air expansion tubes cause the

two shielding plates to make uniform surface contact with the frame inner

surfaces.

(a) Fingerstock doors can provide over 80 decibels of shielding to

magnetic fields from 100 kilohertz through 30 megahertz and greater SE to

plane waves and electric fields. Air-expandable doors can provide greater

than 120 decibels of magnetic field SE from 10 kilohertz to 10 gigahertz.

(b) Air-expandable doors require an air source and air controls with

back-up in safety controls. They also require very strong steel frames and,

as a result, are more expensive than gasketed doors. They are also more

difficult and costly to maintain. The air-expandable door would thus be used

only when a large safety margin of HEMP shielding is needed or when equipment

to be protected is extremely sensitive to HEMP or other EM interference.

(c) The waveguide entry tunnel acts as a WBC that will typically

have a cutoff frequency* in the 60-megahertz region. Thus, the higher

frequencies in the HEMP spectrum will penetrate it. Doors are therefore

required to prevent the higher frequency signals from penetrating. Since only

high frequencies can propagate through, doors have good attenuation in this

range and can easily provide the required attenuation. Maintenance require-

ments are not as stringent as for doors that must block the entire frequency

spectrum; thus, the waveguide entry tunnel for personnel access is attractive

from a life-cycle cost standpoint. When the facility has a TEMPEST

requirement as well as EMP shielding requirements, the tunnel is usually

designed with interlocking doors, i.e., a door at each end and interlocked so

that only one door can be opened at once, thus preventing any leakage of

classified information during the entry of personnel. The waveguide entry

tunnel also is highly useful in underground or buried facilities because the

overburden attenuates the high frequencies, thus acting to complement the

tunnel attentuation.

________________________

*Cutoff frequency is determined by the relationship Fo = 5900 MHz/W, where W is

the greatest cross sectional dimension in inches. Below cutoff, the waveguide

attenuation is a function of the waveguide length. In practice, the length-to-

width ratio should be 5.

(3) Electrical penetrations. A common feature for electrical

penetrations in a global protection approach is a cable entry vault to prevent

large currents on external conductors from being conducted into the facility.

Ideally, all penetrations should enter a single vault. In some cases,

however, it may be necessary to separate the vault into two compartments or to

use two vaults for penetrations by different types of lines: power, signal

and control, and antenna. The vault must be connected directly to the

external facility ground system. (See chapter 5 for details.) The cable

entry vault serves three purposes: to insure that penetrating conductors do

not cause conducted HEMP energy to enter the protected topology; to contain

and divert penetrator-conducted HEMP energy to the boundary exterior; and to

contain or divert radiant EM energy resulting from the activation of transient

suppression devices subjected to a conducted pulse. Conductive penetrations,

such as a conduit, waveguide, or shielded cable, must have a circumferential

weld or other means of providing good electrical connection at the

intersection with the entry vault.

(4) Transient suppression devices and filters. Transient suppression

devices fill a critical gap in the concept of topological protection. The

necessity of supplying power to a facility and of communicating over cables or

antennas are two major factors contributing to their use. Power lines

entering a facility are typically connected to an unshielded power grid so

that large, conducted currents must be bled off to prevent their entry into a

facility.* These currents are diverted to the exterior boundary of the

topology. This boundary can be an overall external shield or an enclosed en-

trance vault. Antennas, such as for high-frequency (HF) communications, are

designed to gather EM signals (at wavelengths in the EMP frequency spectrum)

and to apply these signals to the center conductor of a shielded cable. The

EMP transients associated with an HF antenna can be, by far, the largest

single signal entering a facility. Transient suppressors often are used in

conjunction with filters. Filters are frequency-selective whereas surge

suppressors are amplitude-selective. Filters often are used to attenuate

transients associated with the nonlinear operation of surge arresters. They

also are used for selectively passing (or stopping) frequency bands as in the

case of antenna cable penetrations. Transient suppressors are an integral

part of the EM topology, demanding specific installation techniques as will be

seen later. A spark gap is a surge suppressor that provides a conducting path

to ground when the voltage across the device exceeds the gap breakdown level.

Spark gaps with a high current capacity do not operate quickly enough to block

all HEMP energy transients entering the vault. For this reason, it may be

necessary to use other protection devices in conjunction with the spark gap.

________________________

*Within a facility, inside shield 1, power lines are often

routed through steel conduits to provide shielding.

(5) Electromagnetic isolation. The electromagnetic isolation concept

involves the use of elements either immune to interaction with EM radiation or

that provide a current path interruption. Optical fibers are examples of

elements immune to EM radiation that can be used to reduce the number of

conductive penetrations. For practical purposes, optical fibers can be used

for long communications links without signal interference from HEMP. Further,

they can be used to enter shielded zones through waveguide below cutoff

penetrations without compromising the EM shielding effectiveness, as figure 3-

6 shows. Where possible, optical fibers are recommended for--

(a) Voice and data communications lines.

(b) Energy monitoring and control systems (EMCS).

(c) Intrusion detection systems.

(d) Other security systems.

(e) Control systems.

(f) Any other use where possible and practical.

(6) Grounding. Some form of grounding is required in any electrical or

electronic system for protecting personnel from electrical shock, controlling

interference, proper shunting of transient currents around sensitive

electronics, and other reasons. (Grounding does not directly provide

protection against EMP, but must be done properly to prevent creation of more

serious EMP vulnerabilities.) Ideally, grounding would keep all system

components at a common potential. In practice, because of possible inductive

loops, capacitive coupling, line and bonding impedances, antenna ringing

effects, and other phenomena, large potentials may exist on grounding

circuits. The choice of grounding concept is therefore important in the HEMP

protection philosophy.

b. Hardening allocation concept. The shielding concepts in this chapter

introduce the concept of hardening allocation in which the overall protection

philosophy specifies degrees of hardening for each zone. The practicality of

this concept usually depends on the complexity of the system to be protected.

If it is determined that an overall SE of 80 decibels is required for the most

sensitive components, but the remaining elements require only 60 decibels,

then zones with different SE may be established. The cost-effectiveness of a

zonal design with a hardening allocation for each barrier must be studied

carefully on a facility/ system specific basis to determine the practicality

of this approach.

c. Shield penetration protection concepts. All shielded zones will

require penetrations to allow entry of equipment, personnel, electric power,

communications, and control signals, ventilation, water, fuel, and various

fluids. Without Protection, these penetrations compromise the shield.

(l) Large access doors. Large access doors are often necessary to

provide an entry for equipment, supplies, or vehicles into EMP hardened

facilities. In facilities that require blast overpressure protection, large

blast doors are used. These doors generally use one or more thick steel

plates to provide protection. The door's inherent shielding ability is thus

high, but its large size presents a difficult gasketing problem. If blast

protection is not required, it is still necessary to design the door with a

high degree of structural strength. This step is to ensure that the door can

provide the necessary gasket compression force and that proper mechanical

alignment of closure contact surfaces is maintained.

(2) Personnel entrances. Two concepts are commonly used for personnel

entrances: conventional EMP/RFI shielded doors and personnel tunnels that act

as waveguides below cutoff. The shielded doors generally use metal

fingerstock or EMI/RFI gaskets to provide an electromagnetic seal around the

door jamb periphery. Currently available gasket and fingerstock doors require

regularly scheduled maintenance and/or replacement to maintain required

shielding levels. The gaskets are relatively easily damaged and also require

replacement. Air-expandable doors may also be used, although they typically

have more maintenance problems. These doors generally use a movable

subassembly of two shielding plates on a framework that is moved on rollers in

and out of a steel-framed opening. When closed, air expansion tubes cause the

two shielding plates to make uniform surface contact with the frame inner

surfaces.

(a) Fingerstock doors can provide over 80 decibels of shielding to

magnetic fields from 100 kilohertz through 30 megahertz and greater SE to

plane waves and electric fields. Air-expandable doors can provide greater

than 120 decibels of magnetic field SE from 10 kilohertz to 10 gigahertz.

(b) Air-expandable doors require an air source and air controls with

back-up in safety controls. They also require very strong steel frames and,

as a result, are more expensive than gasketed doors. They are also more

difficult and costly to maintain. The air-expandable door would thus be used

only when a large safety margin of HEMP shielding is needed or when equipment

to be protected is extremely sensitive to HEMP or other EM interference.

(c) The waveguide entry tunnel acts as a WBC that will typically

have a cutoff frequency* in the 60-megahertz region. Thus, the higher

frequencies in the HEMP spectrum will penetrate it. Doors are therefore

required to prevent the higher frequency signals from penetrating. Since only

high frequencies can propagate through, doors have good attenuation in this

range and can easily provide the required attenuation. Maintenance require-

ments are not as stringent as for doors that must block the entire frequency

spectrum; thus, the waveguide entry tunnel for personnel access is attractive

from a life-cycle cost standpoint. When the facility has a TEMPEST